Working Pressure up to 160 bar / 320 bar / 400 bar

Suitable for various flow rates and appropriate Inlet / Outlet connections ( Threaded & Flanged ), tailor made to suit specific applications. Raw material selection depends upon working pressures.

Working Pressure Upto 160 bar

Service & replacement of Filter Elements without interrupting the system with 1/2", 3/4" & 1" BSP Inlet / Outlet connections.

Working Pressure Upto 10 bar

Catches wear from total system components & restrict the entry into the reservoir.

Working Pressure Upto 5 bar

Offline filtration enables continuous, multi-pass filtration to clean the oil from a particular NAS Level ( Normlly what is available in the open market ) to the desired much finer NAS level depending upon applications and hence protect the entire Hydraulic System and its costly components.

Visual Clogging Indicators

Visual Clogging Indicators

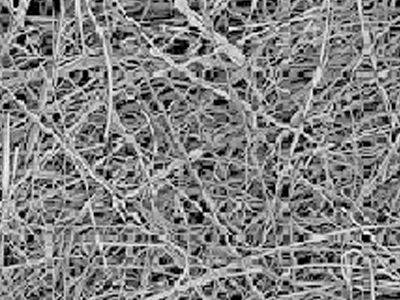

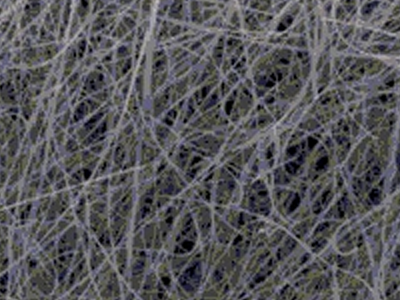

The hydraulic fluid is the most important element of the hydraulic system. It enables the power transmission and affects the discharge of heat as well as the greasing of moving parts. The type of hydraulic fluid determines the efficiency, the pressure level, the temperature level, the materials and the sealing materials to be used. Furthermore, the hydraulic fluid has a decisive influence on the filterability and with this also influence the use of different filter media.

Hence, in a hydraulic system, filtration leads not only to an extension of lifetime of the components, but it also influences service life of the fluid itself.

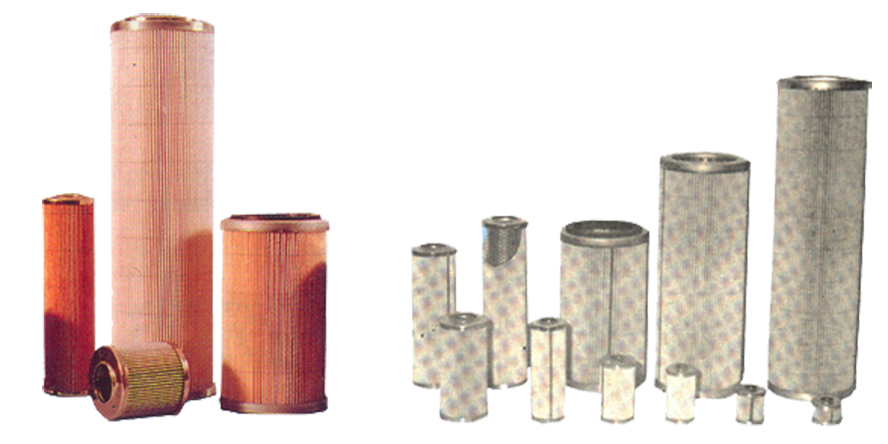

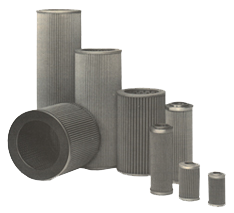

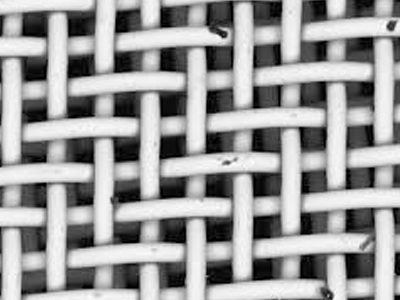

The filtering Media & Supporting wire mesh around a thick perforated supporting tube are affixed to the top & bottom covers with special adhesives for high collapse ratings. Depending upon the type of system and filtration fineness required commonly available medias are :

Special / Replacement elements as per customers requirements can also be supplied.