Every hose has a finite life depending on the service conditions to which it is exposed. If a hose is subjected to conditions more severe than recommended limits, then its life will be significantly reduced. Variable factors, which can affect the actual service Life, include :

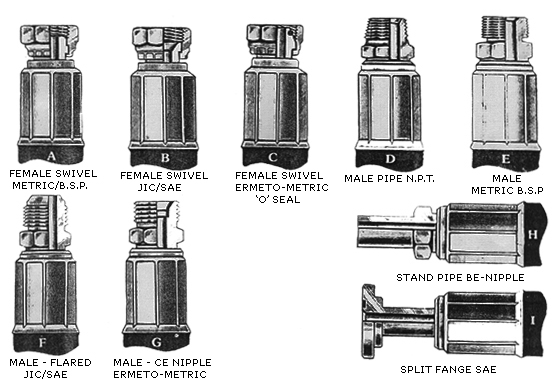

NOTE : ALL THE ABOVE FITTINGS ARE ALSO AVAILABLE IN 45° AND 90° SHORT OR SWEPT ELBOWS.

STANDARD END FITTINQS ( THREADS / SIZE ) ON DIFFERENT SIZES ( I.D. ) OF HOSES

| HOSEDASH SIZE | HOSE I.D. | METRIC ASSY REF A, E, G |

ERMETO METRIC '0' SEAL REF, C |

B.S.P. ASSY REF. A, E | N.P.T. ASSY REF.D | U.N.F JIC/SAE REF. B, F | B.E.NIPPLE REF.H | FLANGES REF.I | |

|---|---|---|---|---|---|---|---|---|---|

| 3000 PSI | 6000 PSI | ||||||||

| -3 | 3/16" | M.12X1.5 | M.16X1.5 | 1/4" | 1/8" | 7/16"-20 | 6ØX2OMML 8ØX2OMML | - | - |

| -4 | 1/4" | M.14X1.5 | M.18X1.5 | 1/4" | 1/4" | 1/2"-20 | 8ØX2OMML 1OØX24MML | - | - |

| -5 | 5/16" | M.16x1.5 | M.20X1.5 | 3/8" | 3/8" | 9/16"-18 | 1OØX24MML 12ØX25MML | - | - |

| -6 | 3/8" | M.18X1.5 | M .22x1.5 | 3/8" / 1/2" | 3/8" | 9/16"-18 5/8" -18 |

12ØX25MML 14ØX27MML | 30.2mm | 31.7MM |

| -8 | 1/2" | M.22x1.5 M24X1.5 | M.24x1.5 | 1/2" / 5/8" | 1/2" | 3/4"-16 7/8"-14 |

15ØX25MML 16ØX3OMML | - | - |

| -10 | 5/8" | M.26x1.5 M30x2 | M.30X2 | 3/4" | 3/4" | 11/16"-12 | 18ØX25MML 2OØX32MML | - | - |

| -12 | 3/4" | M.30x1.5 M36x2 | M.36X2 | 3/4" / 1" | 3/4" | 1 1/16"-12 1 5/16"-12 |

22ØX25MML 25ØX34MML | 38.1mm | 41.3mm |

| -16 | 1" | M.36x2 M38X1.5 M42x2 | M.42x2 | 1" / 1 1/4" | 1" | 15/16"-12 15/8"-12 | 28ØX25MML 3OØX36MML | 44.5mm | 47.6mm |

| -20 | 1 1/4" | M.45x2 M52X1.5 | M.52x2 | 11/4"/ 1 1/2" | 1 1/4" | 1 7/8"-12 | 35ØX3OMML 38ØX38MML | 50.8mm | 54.0mm |

| -24 | 1 1/2" | M.52X2 | M.52X2 | 11/2" / 2" | 1 1/2" | 2 1/4--12 | 42ØX36MML 5OØX7OMML | 60.3mm | 63.5mm |

| -32 | 1" | M.65x2 | M.65x2 | 2" / 2 1/2" | 2" | 2 1/2-.12 | 71.4mm | 79.4mm |